This information may also be used for creating Work Instructions, Inspection Sheets or as an input to Control Plans. First of all, it can be a seismic change for some organizations, particularly those with an established process primarily focused on profitability and cost reduction. The quality function deployment steps had shown promising and successful sales result in the 1970s and have ever since been adopted by a variety of industries. With the use of matrix diagrams, or House of Quality, it is possible to pin-point selective customer-driven product advertising and service attributes.

In fact, Clausing tells of an engineer who initially wanted to place the emergency hand brake of a sports car between the seat and the door. However, the voice of customer testing found that women drivers wearing skirts had difficulty with the new placement of the hand brake. The Quality Function Deployment highlighted potential dissatisfaction with the location of this feature, and the idea was scrapped.

Introduction to Quality Function Deployment (QFD)

Quality Function Deployment benefits companies primarily by ensuring they bring products to market that customers actually want, thanks to listening to customer preferences at the beginning of the design process. Then, mandating these needs and desires is met throughout every aspect of the design and development process. Removing debris from air flow, for example, is one of the main functions of a hair dryer. The last row of the matrix captures the “how much” values for the functions. The function removing debris from air flow, for example, has a corresponding “how much” cell where it is noted that the screen apertures have to be 1 mm maximum. Removing moisture from hair, for example is one of the main functions of a hairdryer.

The traditional design approach may have tended to develop solutions and commit to designs early in the product development process. Designers and engineers would not have ignored the VOC completely; but, by choosing designs too early there was an increased risk that the solution offered did not fully meet requirements. A product specification may have been written, but it may have been a retrospective record of the finished design. Designers and engineers would not have ignored the voice of the customer completely; but by choosing designs too early, there was an increased risk that the solution offered did not fully meet requirements. The QFD1 matrix enables the relationship between the following two sets of elements, customer requirements (or product attributes) and engineering requirements (or product functions), to be explored. In this example, the customer requirements are broken down in a tree structure including three levels.

What is the House of Quality?

This limits the freedom of designers to ‘play with’, relationships between the physical nature and the functional nature substantially. The preferences of the consumer are then placed in a matrix called the House Of Quality. The matrix is also populated with the known capabilities of the organization at each step of the product development process. The matrix then makes it possible to cross-reference the needs of the consumer against that function deployment which the business can achieve. By doing this, the matrix reveals the best product the organization is able to create for the consumer and enables the integration of the consumer needs and wants throughout the development of the product. Although it might sound like a modern testing methodology, Quality Function Deployment (QFD) has a 50-year track record of putting customer needs first throughout the entire product development process.

In many markets, you could have expected many makes of car to have serious body and chassis rust, within a few years after manufacture. Toyota Auto Body used QFD to resolve this problem in their new vehicle design programmes (Eureka 1987). The technical difficulty of meeting the need and achieving the target value.

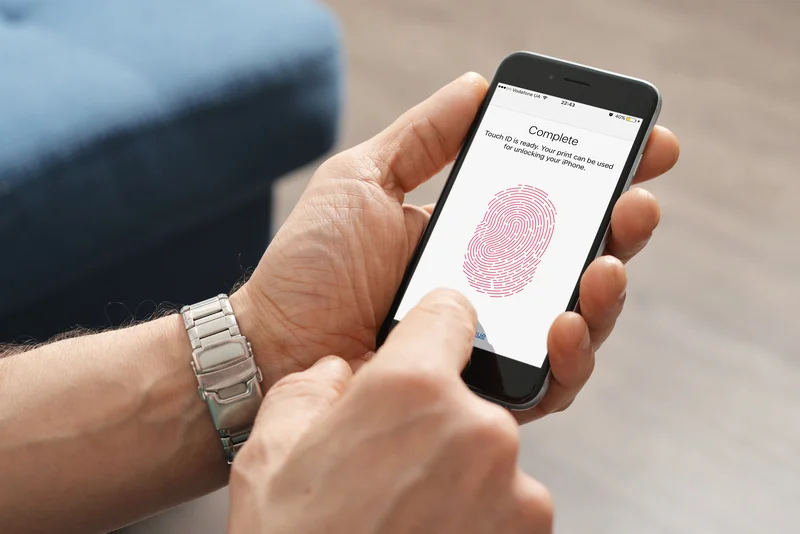

Once information about customer expectations has been obtained, techniques such as quality function deployment can be used to link the voice of customer directly to internal processes. It allows the consideration of the “voice of the customer” along the service development path to market entry. The features or qualities of a product or service that customers deem significant and that contribute to their satisfaction are known as customer requirements. These requirements may be aesthetic (such as design, color, or packaging) or functional (such as performance, reliability, or ease of use). In order to make the QFD process easier to follow, make sure that customer requirements are precise, quantifiable, and clearly defined.

- The matrix then makes it possible to cross-reference the needs of the consumer against that which the business can achieve.

- The main benefit of QFD is that it ensures the customer is considered in both the design and development process, resulting in products that are more likely to satisfy your customers.

- A large financial institution wanted to create a new model for a brick and mortar banking center.

- Quality function deployment (QFD) is a methodology for gathering customer requirements and turning them into products or services.

Based on Mitsubishi’s success, the approach soon caught on in other industries in Japan. Toyota used the technique in developing automobiles, and from Toyota it spread to the American automobile industry (most notably Ford Motor Company). QFD is now making headway in other industries, including defense, aerospace, and other high technology areas.

Quality function deployment (QFD) is a quality management tool that can help you do that. QFD is a structured approach to incorporating customers’ needs and requirements into every stage of product development, from planning and design to manufacturing and delivery. The customer requirements are simply fed into the rows and the design requirements fed into the columns.

The very meaning of quality function deployment asks to continue helping and responding to customer’s inquiries and calls even after the product is so-called “finished and sold”. The aim of quality function deployment qfd is integrated with customer feedback. QFD helps businesses streamline their processes and make them more efficient. Businesses can avoid quality issues and save time and money by optimizing their processes.